TPU vs PVC vs TPH PPF: Paint Protection Film Full Comparison

A pristine paint job is the pride of every car owner. However, daily exposure to road debris, UV rays, bug splatters, and minor abrasions can deteriorate your car’s exterior over time. This is where paint protection film (PPF) steps in, acting as an invisible shield that preserves the vehicle’s paint while maintaining its showroom finish. With the increasing demand for high-quality automotive protection, manufacturers have developed various PPF materials, each offering different levels of durability, flexibility, and protection. Today we’ll compare the three most three common types of paint protection film:

• TPU PPF (Thermoplastic Polyurethane) – The premium choice with self-healing properties.

• PVC PPF (Polyvinyl Chloride) – The budget-friendly alternative with basic protection.

• TPH PPF (Thermoplastic Polyolefin) – A mid-range option offering decent protection at a lower cost.

What is Paint Protection Film (PPF)?

Paint Protection Film (PPF) is a transparent polyurethane or polymer-based film applied to a car’s exterior to protect it from scratches, chips, chemical stains, and environmental damage. This film is commonly installed in high-impact areas such as:

• Front bumper and hood – Protects against rock chips and road debris.

• Side mirrors and door edges – Prevents scratches from accidental bumps.

• Headlights and fog lights – Shields against oxidation and discoloration.

With options ranging from glossy to matte PPF, car owners can also enhance their vehicle’s aesthetics while ensuring long-term protection. Its core performance depends on the scientific composition of materials and manufacturing technology. We will analyze the key components of PPF from a materials science perspective, comparing the thickness and pricing of mainstream market products to help you make an informed choice.

Base Layer: The Core Determinant of Protection Performance

The base layer of PPF is its fundamental structure, directly affecting paint protection performance and durability. Below is an in-depth analysis of four mainstream base materials.

1. TPU PPF – Thermoplastic Polyurethane

The Ultimate Protection Solution

Thermoplastic Polyurethane (TPU) PPF is widely regarded as the gold standard in paint protection. Its high-end composition offers:

Self-Healing Technology – Scratches disappear with heat exposure.

Superior Durability – Resists impact damage, stains, and chemical etching.

Flexible & Easy to Install – Conforms smoothly to curved surfaces.

UV & Yellowing Resistance – Maintains optical clarity for years.

Chemical Structure: Composed of diisocyanates (MDI/HDI), polyols (polyester/polyether), and chain extenders, forming a microphase-separated structure with hard segments (urethane groups) and soft segments (polyols).

- Key Subtypes:

- Aromatic TPU: Uses MDI monomers, containing benzene rings in its hard segments, absorbing UV light at 280-400nm. Prone to photodegradation, with a yellowing rate 3-5 times faster than aliphatic TPU.

- Aliphatic TPU: Uses HDI monomers with straight-chain alkane structures, offering superior UV resistance. After 2000 hours of QUV testing, the ΔE color change remains below 2.

- Mechanical Performance: Tensile strength of 20-50 MPa, elongation at break of 500-800%, and maintains elasticity across temperatures ranging from -40°C to 100°C.

- Market Share: The dominant material in the high-end market, with costs ranging from $2 to $5 per square foot, accounting for over 75% of the global PPF market.

Representative Products & Pricing

- Aromatic TPU: XPEL Ultimate Plus

- Thickness: 8 mil

- Price per roll (1.5m × 15m): $605 – $726

- Features: A leading product in the high-end market with a 10-year warranty and excellent self-healing capabilities.

- Aliphatic TPU: XPEL Fusion Plus

- Thickness: 10 mil

- Price per roll (1.5m × 15m): $1,089 – $1,210

- Features: A premium product with a 10-year warranty and outstanding anti-yellowing performance.

If you’re looking for long-lasting, high-quality car paint protection, TPU PPF is the best option. While it is the most expensive, it provides unmatched durability, making it a worthwhile investment for luxury vehicles and high-performance cars. And here is another post about TPU PPF Installation Cost.

2. PVC PPF – Polyvinyl Chloride

Basic Protection for Budget-Conscious Buyers

Polyvinyl Chloride (PVC) PPF is the most economical option, but it has several significant drawbacks:

Lack of Flexibility – Difficult to apply on curved surfaces.

Prone to Yellowing – Fades over time due to UV exposure.

Limited Durability – Provides only basic scratch protection.

- Molecular Structure: A linear polymer formed through free radical polymerization of vinyl chloride monomers, containing a high concentration of polar C-Cl bonds.

- Performance Characteristics:

- High modulus (2-4 GPa) provides excellent puncture resistance, but low elongation at break (100-200%) leads to poor flexibility.

- Glass transition temperature (Tg) of approximately 80°C makes it prone to softening and deformation at high temperatures.

- Contains halogen elements, leading to degradation under prolonged UV exposure, with a yellowing index (YI) exceeding 10, causing visible discoloration.

- Market Status: Costs less than $0.50 per square foot but has been largely phased out of mainstream markets, remaining only in low-end products.

Representative Product & Pricing

- 3M Scotchgard Pro Series

- Thickness: 6-8 mil

- Price per roll (1.5m × 15m): $121 – $194

- Features: A common choice in the low-end market, with a 2-3 year warranty, suitable for short-term use.

While PVC PPF is suitable for temporary protection, it does not offer the long-term benefits of TPU or TPH. Car owners looking for lasting performance should consider TPU PPF instead.

3. TPH PPF-Thermoplastic Polyolefin Hybrid

The Budget-Friendly Alternative

Thermoplastic Polyolefin (TPH) PPF is a hybrid material that balances cost and performance. While it does not offer self-healing properties like TPU, it still provides:

Good Scratch Resistance – Protects against minor abrasions.

Moderate Flexibility – Easier to install than PVC.

Affordable Price Point – A cost-effective alternative to TPU.

- Chemical Composition: TPH is an upgraded version of PVC, created by blending polyolefins (such as PE/PP) with PVC, essentially forming a PVC-based elastomer.

- Performance Characteristics:

- Mechanical Properties: Tensile strength of 15-25 MPa, elongation at break of 200-400%, and tear resistance of 50-80 kN/m.

- Weather Resistance: Extended yellowing resistance up to 2-3 years but still inferior to aliphatic TPU.

- Environmental Concerns: Contains chlorine elements, making it non-compliant with the EU REACH regulation on halogens.

- Market Positioning: Positioned as a cost-effective alternative to PVC in the mid-to-low-end market.

Representative Product & Pricing

- LLumar Valor

- Thickness: 8 mil

- Price per roll (1.5m × 15m): $290 – $363

- Features: A high-end TPH product with a 5-year warranty, emphasizing affordability.

TPH PPF is ideal for those who want decent paint protection at a lower cost. However, it may wear out faster over time, especially in harsh weather conditions.

TPU vs TPHPVC vs TPH PPF: Feature Comparison

|

Feature |

TPU PPF | PVC PPF | TPH PPF |

| Cost | Low | Low | Moderate |

| Durability | Basic | Basic | Good |

| Flexibility | Low | Low | Moderate |

| Self-Healing | No | No | No |

| UV Resistance | Poor | Poor | Moderate |

| Yellowing Resistance | Low | Low | Moderate |

Functional Coatings: Engineered Surface Enhancements

The functional coatings of PPF add value through self-healing, hydrophobic, and optical enhancements.

1. TPU Self-Healing Coating

- Technology Principle: Designed with a microphase-separated structure, where hard segments provide mechanical strength and soft segments (such as polycaprolactone, PCL) enable shape memory functionality.

- Healing Efficiency: Over 95% (based on ASTM D968 standards).

2. Hydrophobic Coating

- Biomimetic Design: Utilizes nano-imprint technology to create a lotus-leaf-like micro-nano structure (Ra ≈ 100nm).

- Performance Metrics: Contact angle >110°, roll-off angle <10°.

3. Optical Coating

- Material Design: Incorporates nano SiO₂ (20-50nm particle size) to enhance refractive index to 1.48-1.52.

- Light Transmission: >92% (ASTM D1003 standard).

Adhesive Layer: Breakthroughs in Interface Science

The adhesive layer plays a crucial role in ensuring proper adhesion and removability.

1. Pressure-Sensitive Adhesive (PSA)

- Chemical Composition: Base polymer consists of acrylic copolymers with hydrogenated petroleum resin as a tackifier.

- Rheological Properties: Storage modulus (G’) remains in the range of 10⁴-10⁵ Pa within 0.1-10 Hz frequency.

2. Smart Adhesive Technology

- Humidity-Responsive: Incorporates polyethylene glycol (PEG) segments, allowing reversible hydrogen bond dissociation in the presence of water.

- Thermal Release: Includes low-melting-point microcrystalline wax (melting at 60-70°C), reducing adhesion by 80% when heated.

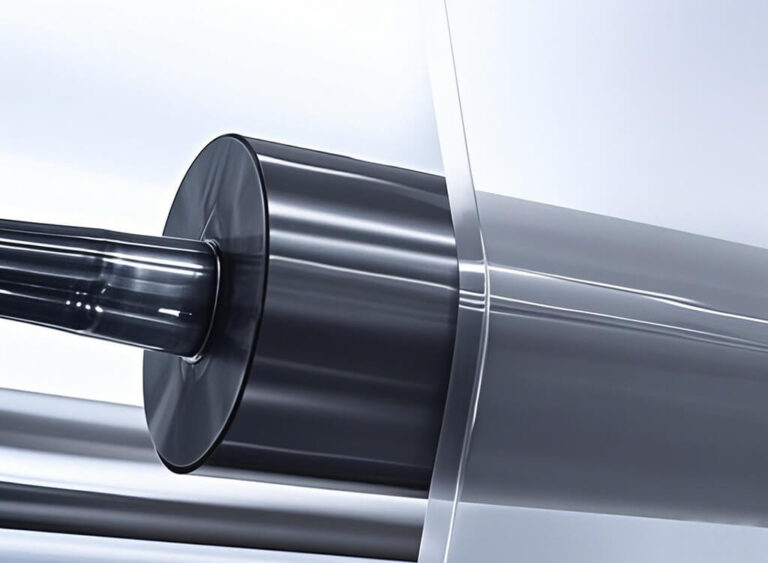

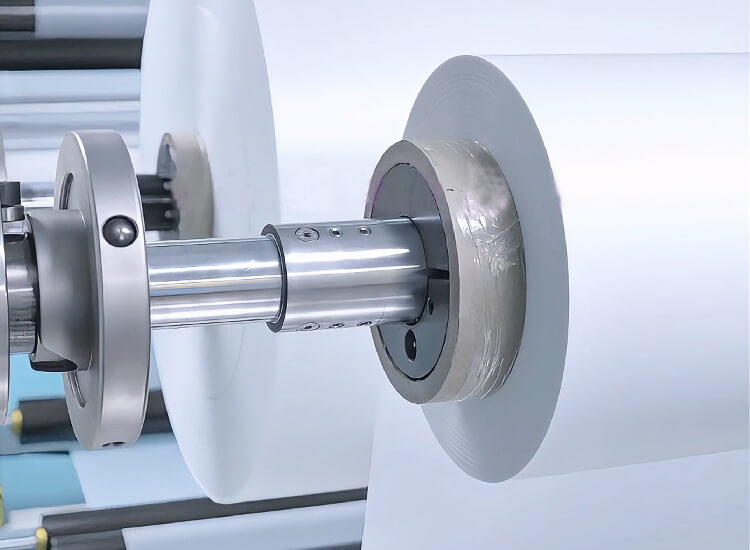

TPU/TPH/PVC Paint Protection Film Manufacturing Process

TPU PPF

Made from high-performance thermoplastic polyurethane (TPU) through precision extrusion molding, followed by the application of self-healing, hydrophobic, and anti-stain coatings. After curing, it offers excellent flexibility, weather resistance, and scratch resistance while maintaining long-term optical clarity.

TPH PPF

Produced by blending thermoplastic polyolefin (TPO) with PVC, then undergoing extrusion molding and a basic protective coating application. It is more flexible than PVC but less durable than TPU, making it a balanced choice for those seeking both affordability and performance.

PVC PPF

Manufactured using polyvinyl chloride (PVC) mixed with plasticizers, processed through extrusion and calendering, and coated with a basic UV-resistant layer. It is the most cost-effective option but is prone to yellowing, has higher rigidity, and is more challenging to install, making it suitable for short-term protection needs.

Post: Paint Protection Film Manufacturing Process in Factory

Leading Paint Protection Film Manufacturers

XPEL – Industry Leader in Premium PPF

XPEL Ultimate Plus and XPEL Stealth are known for superior self-healing and hydrophobic performance.

High-end pricing but excellent PPF durability and brand reputation.

3M – Trusted Brand in Protective Films

3M Scotchgard Pro Series offers good protection, though mainly mid-range TPU PPF.

Well-established global distribution network.

LLumar – Reliable Paint Protection Film Supplier

LLumar Valor PPF balances performance and affordability, making it a popular mid-range option.

Which PPF is Best for Your Car?

If you want top-tier paint protection, TPU PPF is the clear winner. While TPH PPF provides a good balance between affordability and durability, PVC PPF is best suited for temporary use or budget-conscious buyers.

Market Price Statistics of TPU/PVC/TPH PPF

| PPF Material Type | Representative Product | Thickness | Roll Price (1.5m×15m) | Warranty |

| PVC PPF | 3M Scotchgard Pro | 6-8 mil | $121 – $194 | 2-3 years |

| TPH PPF | LLumar Valor | 8 mil | $290 – $363 | 5 years |

| Aromatic TPU PPF | XPEL Ultimate Plus | 8 mil | $605 – $726 | 10 years |

| Aliphatic TPU PPF | ELOV Premium TPU PPF | 8-10 mil | $150 – $350 | 10 years |

Conclusion: Invest in the Best Paint Protection Film

When it comes to protecting your vehicle’s paint, choosing the right PPF material makes all the difference. TPU PPF remains the industry leader due to its self-healing capabilities, superior durability, and long-term UV resistance.

Looking for a Reliable PPF OEM Manufacturer?

If you’re a distributor, wholesaler, or brand owner searching for high-performance TPU PPF, consider working with ELOV, a leading China-based Paint Protection Film manufacturer known for:

OEM & Private Label Services – Custom branding for your market

High-Quality Raw Materials – Premium TPU from Covestro.

Advanced R&D & Manufacturing – 96,000㎡ factory with 8 production lines.

Competitive Factory Prices – Low wholesale price and 1-roll MOQ.

| ELVO Offers Fast Paint Protection Film OEM |

| 25 Days |

| From Ideas To Mass Production |

| Start OEM For Your Brand Now! |