Color Stability Science: Why ELOV’s Colored and Matte PPF Films Resist Fading

For distributors and installers in the PPF business, color stability isn’t just a technical specification—it’s the foundation of your reputation and profitability. When a customer invests in a colored or matte wrap, they expect the bold, sophisticated look to last. Fading, yellowing, or color shift leads to costly warranty claims, unhappy customers, and damage to your brand’s credibility.

At ELOV PPF factory(https://www.elovppf.com/), we engineer our colored and matte Paint Protection Films to defy fading. This isn’t achieved through simple dyes or surface coatings; it’s the result of a fundamental scientific approach integrated at every stage of production. Here’s a deep dive into the science that ensures ELOV films maintain their intended appearance for years.

The Core Challenge: Why Most Films Fade

Traditional color films fail due to a few critical weaknesses:

-

UV Photodegradation: Ultraviolet radiation is the primary enemy. It breaks down chemical bonds in pigments, dyes, and the film matrix itself, causing colors to bleach, shift, or develop a yellow cast.

-

Pigment/Binder Incompatibility: If colorants are not perfectly compatible with the TPU polymer, they can migrate, cluster, or be exposed at the surface, leading to uneven fading and chalkiness.

-

Surface Oxidation and Contamination: The top layer of the film constantly battles environmental oxidants, pollutants, and chemical contaminants that can etch into and degrade the surface finish.

-

Poor Thermal Stability: Repeated heat cycles from the sun can cause physical and chemical changes in inferior materials, accelerating the degradation process.

The ELOV Solution: A Multi-Layer Defense System

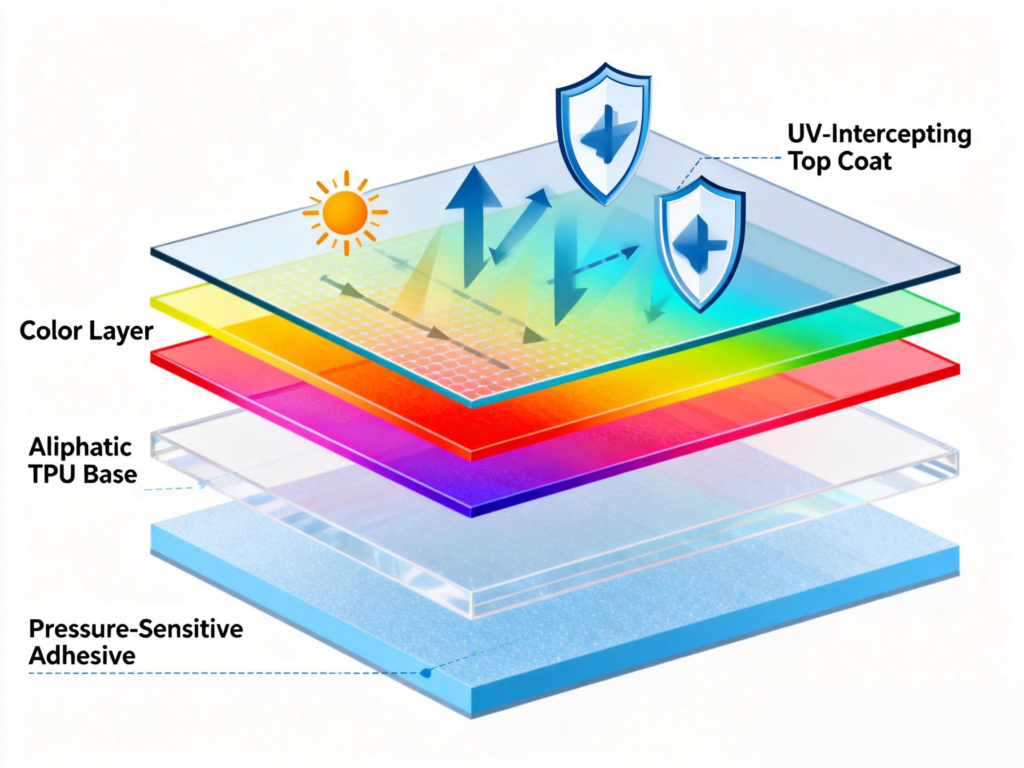

We combat fading not with one magic ingredient, but with a synergistic, multi-layered defense system built into the film’s architecture.

1. The Foundation: Premim, Inherently Stable Aliphatic TPU

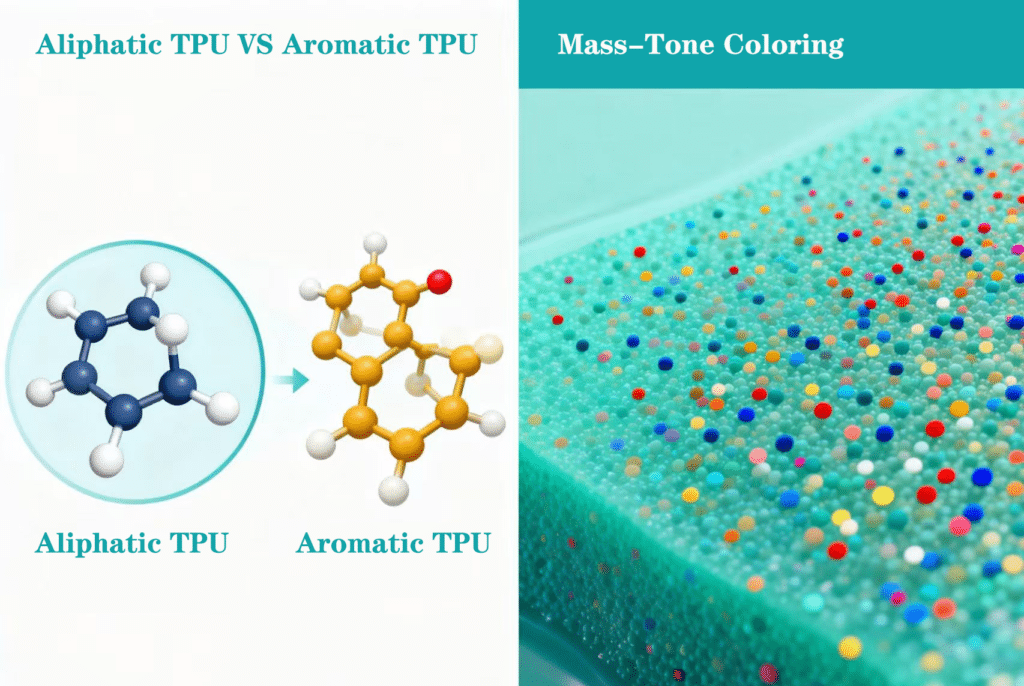

Our starting point is our proprietary aliphatic thermoplastic polyurethane base. Unlike cheaper aromatic TPU that yellows rapidly under UV exposure, aliphatic TPU has a molecular structure lacking light-absorbing benzene rings. This makes it inherently resistant to UV-induced yellowing, providing a crystal-clear, stable base that will not undermine the true color applied to it.

2. The Heart: Deep-Body, Polymer-Integrated Pigmentation

This is where we fundamentally differ from surface-coated films. We do not merely print or laminate a color layer on top.

-

Mass-Tone Coloring: Our color is integrated throughout the entire thickness of the film during the polymer phase. This “deep-body” or “mass-tone” method means the color is an intrinsic property of the material, not a vulnerable surface layer.

-

High-Performance Pigments: We exclusively use high-grade, inorganic, and selected organic pigments known for exceptional lightfastness and thermal stability. These pigments are engineered to reflect or absorb specific wavelengths of light without breaking down.

-

Molecular Bonding: Our proprietary process ensures these pigments are uniformly dispersed and chemically compatible with the TPU polymer chains. This prevents pigment migration (leading to blotchiness) and ensures even, consistent color that wears evenly, not off.

3. The Shield: Advanced, UV-Intercepting Top Coat

For matte and colored PPF, the top coat is a critical, active defense layer, not just a clear cover.

-

UV Absorbers & HALS: Our top coat is loaded with a high concentration of permanent UV absorbers (UVAs) and Hindered Amine Light Stabilizers (HALS). UVAs act like sunscreen, absorbing harmful UV radiation and converting it to negligible heat. HALS are “radical scavengers” that neutralize the free radicals created by UV exposure, stopping the degradation chain reaction before it can damage the color layer beneath.

-

Matte Finish Integrity: For our Matte PPF(https://www.elovppf.com/matte-paint-protection-film/), the low-gloss finish is achieved through a precision-engineered micro-textured top coat, not by adding flattening agents that can wear off. This texture is durable and protected by the same UV-stabilized coating, preventing it from becoming glossy or patchy over time.

4. The Proof: Rigorous Accelerated and Real-World Testing

Every ELOV colored ppf and matte ppf series must pass our brutal testing protocols before release:

-

QUV Accelerated Weathering: Samples undergo thousands of hours in QUV chambers, simulating years of intense sun, rain, and thermal cycling. We measure color change (Delta E) against international standards (SAE J2527, ASTM G155). A low Delta E value confirms minimal fading.

-

Xenon Arc Testing: This test replicates the full solar spectrum, including visible and infrared light, for a complete picture of long-term color and gloss stability.

-

Outdoor Weathering: We maintain test panels in diverse, harsh climates to validate our lab data against real-world conditions.

Your Competitive Advantage: Selling Confidence

When you choose ELOV colored and matte PPF, you’re not just selling a film; you’re selling durable confidence to your customers and business peace of mind to yourself.

-

Eliminate Costly Comebacks: Dramatically reduce warranty claims related to fading, discoloration, or uneven wear.

-

Command a Premium Price: Offer and confidently stand behind longer warranty periods for color stability, justifying higher price points.

-

Build a Trusted Brand: Become known for installations that look great not just on day one, but for years to come. Satisfied customers become your best marketers.

-

Simplify Your Inventory: Rely on a product line where every finish—gloss, matte, satin, color—is built to the same enduring standard.

Conclusion: An Investment in Long-Term Aesthetics

In the world of vehicle wraps, the true test of quality is time. ELOV PPF Factory(https://www.elovppf.com/) commitment to color stability science ensures that the dramatic transformation you create endures. We fuse advanced polymer chemistry, precision manufacturing, and relentless testing to deliver films that protect their own beauty as fiercely as they protect the paint underneath.

Ready to offer colors that last?(https://www.elovppf.com/contact-us/) Contact ELOV today to request color swatch books, technical data sheets, and samples to see the enduring difference for yourself.