Thermoplastic Polyurethane (TPU) Paint Protection Film (PPF): What Is It?

In the ever-evolving world of automotive care, Paint Protection Film (PPF) has emerged as one of the most effective solutions for maintaining a vehicle’s exterior finish. But behind the high gloss and durability lies a remarkable material: Thermoplastic Polyurethane (TPU). This article dives deep into what makes TPU film for automotive applications so critical and how it’s transforming the paint protection industry.

What is Thermoplastic Polyurethane (TPU)?

Thermoplastic Polyurethane (TPU) is a versatile type of polyurethane plastic that stands out for its excellent flexibility, crystal-clear transparency, and strong resistance to oil, grease, and surface wear. In the automotive industry, TPU is widely used to manufacture paint protection films that are applied directly to a vehicle’s painted surfaces. Unlike traditional plastics, TPU has a unique molecular structure that allows it to be stretched and reformed without losing its integrity. These qualities make it ideal for flexible TPU automotive protective coatings that must conform to the curves of a vehicle.

Applications of TPU in the Automotive Film Industry

Thermoplastic Polyurethane (TPU) has become the gold standard material in the automotive film industry, especially for high-end paint protection film (PPF). Its unique combination of flexibility, optical clarity, and self-healing properties makes it ideal for preserving a vehicle’s appearance against everyday wear and tear. When applied as a surface layer in automotive paint protection films, TPU film provides a durable, invisible shield that guards against scratches, stone chips, bird droppings, UV rays, and chemical contaminants—all while maintaining a sleek, showroom-quality finish.

Beyond paint protection, TPU films are also widely used for headlight protection, offering impact resistance and yellowing prevention to keep lenses crystal clear. In windshield protection film applications, TPU provides a nearly invisible barrier that helps prevent cracks or chips from road debris, reducing the need for costly replacements. The use of TPU in interior automotive surface protection—such as on infotainment screens, piano-black trim, and dashboards—also continues to grow, thanks to its fingerprint resistance and long-lasting clarity.

As the automotive market shifts toward higher expectations for both aesthetics and protection, TPU-based automotive films have become the preferred choice among OEMs, PPF installers, and detailing professionals. With its balance of strength, elasticity, and transparency, TPU technology continues to push the boundaries of what modern vehicle protection can achieve.

TPU PPF Manufacturing Process Overview

Creating high-performance TPU paint protection film (PPF) involves a series of advanced PPF manufacturing steps that ensure the film meets the demands of real-world automotive environments. Here’s an inside look at how automotive TPU protective films are made:

-

Raw Material Selection

The process starts with sourcing high-grade aliphatic TPU resin, known for its non-yellowing, UV-resistant properties. Leading manufacturers often partner with global chemical giants to guarantee material quality and consistency. -

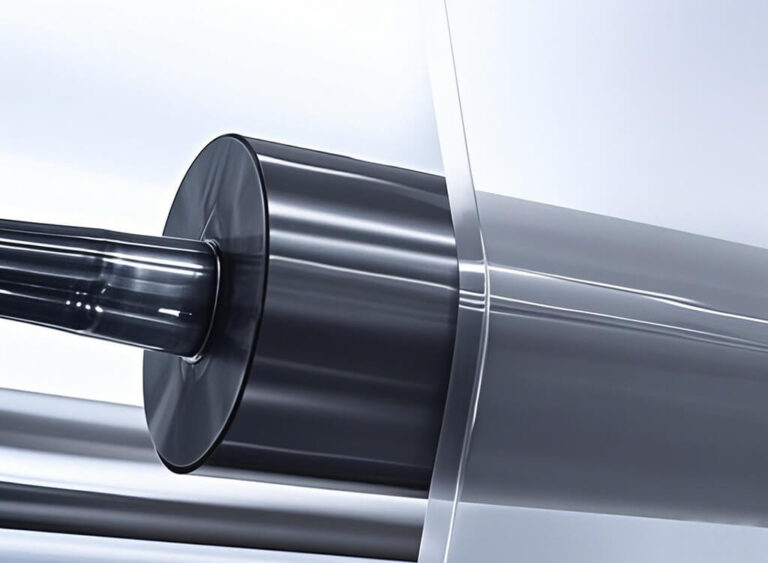

Extrusion and Casting

The TPU resin is melted and extruded into thin sheets using precision equipment. This step defines the TPU film thickness and clarity—both critical for optical performance and durability. -

Multilayer Coating

Advanced PPF typically features a multi-layer construction, including a self-healing top coat, hydrophobic layer, and adhesive backing. Each layer is coated or laminated using cleanroom-grade machinery to ensure surface uniformity. -

Self-Healing Layer Application

The top layer is engineered to self-repair minor scratches when exposed to heat. This self-healing TPU coating for automotive film is typically made using nanotechnology or elastomeric polymers. -

Curing and Surface Treatment

Films are cured to enhance durability and receive treatments like anti-fouling, anti-yellowing, or ceramic coating for added protection. These treatments elevate the TPU film performance in extreme weather and under harsh contaminants. -

Adhesive Lamination

A pressure-sensitive adhesive layer is applied, allowing the film to conform tightly to vehicle surfaces without bubbling or peeling. High-quality adhesives also make the film removable without damaging paint. -

Slitting and Packaging

After quality control checks—including TPU PPF optical inspection and defect detection—the rolls are cut into standard sizes, labeled, and packed under dust-free conditions.

Key Benefits of TPU in Paint Protection Film

Choosing TPU film for car paint protection means choosing advanced protection and performance. TPU offers superior elasticity, self-healing properties, and excellent optical clarity, making it ideal for automotive applications. It provides exceptional durability, hydrophobic properties, UV resistance, and temperature stability, ensuring long-term protection. Additionally, TPU is a more eco-friendly option compared to PVC-based films, reinforcing its role as the preferred choice for high-quality automotive protection.Here are the primary benefits that make TPU the material of choice:

| Feature | Description |

| Superior Elasticity and Conformability | TPU paint protection film with high elasticity easily adapts to complex curves and edges on vehicle surfaces, ensuring seamless coverage and a nearly invisible finish. |

| Self-Healing Properties | Minor scratches and swirl marks vanish when heat is applied—either through sunlight or warm water—thanks to TPU self-healing paint protection film technology. |

| Outstanding Optical Clarity | TPU film clarity and transparency for car wraps enhance the appearance of your vehicle while preserving the original paint color without yellowing over time. |

| Exceptional Durability | Designed to endure daily wear and tear, TPU film durability for long-term protection ensures resistance against stone chips, road debris, and high-pressure car washes. |

| Hydrophobic and Stain Resistance | The top layer of TPU automotive protective coating repels water, dirt, oil, bird droppings, and other contaminants—making maintenance effortless. |

| UV and Chemical Resistance | With built-in resistance to sun damage and harsh chemicals, UV-resistant TPU paint protection helps prevent fading and staining. |

| Temperature and Weather Stability | Whether it’s summer heat or winter snow, heat-resistant TPU PPF performs reliably in extreme weather conditions. |

| Environmentally Safer Alternative | Unlike PVC-based films, the TPU film used in premium PPF is non-toxic and more eco-friendly, supporting sustainable automotive detailing. |

TPU vs Other PPF Materials: TPH and PVC

When it comes to Paint Protection Film (PPF), not all materials are created equal. Let’s compare TPU (Thermoplastic Polyurethane) with TPH (Thermoplastic Polyolefin) and PVC (Polyvinyl Chloride), the three most common materials used in automotive paint protection. TPU stands out as the best option for automotive paint protection due to its unmatched combination of features(Detailed comparison: TPU vs TPH vs PVC).

| Property | TPU | TPH | PVC |

| Flexibility | Excellent | Good | Moderate |

| Durability | 5–10 years | 1–3 years | <2 years |

| Self-Healing | Yes | No | No |

| Clarity | High | Moderate | Low |

| Environmental Safety | Non-toxic, Eco-friendly | Varies | Often not eco-friendly |

| Price (per roll 5ft x 50ft) | Higher ($500–$700) | Lower ($250–$400) | Lowest ($150–$250) |

| Top Brands | XPEL, 3M, Suntek, Llumar | Madico, Avery Dennison, FormulaOne | Orafol, Hexis, KPMF |

Key Takeaways:

-

TPU offers superior flexibility, clarity, and durability, making it the material of choice for long-term, high-performance PPF applications.

-

TPH is more affordable but lacks some of the advanced features like self-healing.

-

PVC is the least durable and offers fewer protective properties, often used for short-term applications or as an entry-level option.

ELOV China: Best TPU PPF Choice of low-cost OEM Supplier

ELOV, started in 2013, stands out as a premier TPU PPF manufacturer known for delivering high-quality paint protection films at competitive prices. As a trusted OEM supplier, ELOV provides durable, customizable solutions that cater to a wide range of industries. Whether you’re a wholesaler, distributor, or automotive brand owner, ELOV’s commitment to using top-grade materials, advanced manufacturing processes, and offering flexible OEM solutions ensures that you receive the best value without compromising on quality.

The Science Behind TPU Film Durability

The impressive durability of TPU film stems from its advanced molecular structure, carefully engineered to withstand extreme conditions. At the core of TPU’s strength is its polyether or polyester-based backbone, which provides hydrolytic resistance—protecting the film from degradation due to moisture and humidity.

Furthermore, the aliphatic structure of TPU significantly contributes to its yellowing resistance, keeping the film clear and transparent over time. TPU is also crafted with a multilayer construction, with each layer offering additional protection against external wear and tear. The outermost layer includes special coatings that enhance the film’s self-healing properties, allowing it to recover from minor abrasions, and its hydrophobic qualities prevent dirt, water, and oil from sticking, making the film easy to clean.

These scientific advancements ensure that TPU films provide reliable, long-lasting protection, making them an excellent choice for automotive paint protection that maintains its functionality and appearance under demanding conditions.

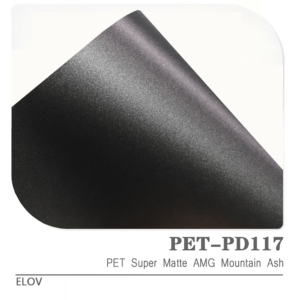

Custom Solutions and Finishes in TPU Films

Manufacturers provide a wide range of customizable TPU film solutions for car wraps, offering various options to suit diverse needs. These include a variety of colors, allowing for both bold and subtle designs. Customers can also choose from different textures such as gloss, matte, and satin finishes, depending on the desired aesthetic. Additionally, thickness levels can be adjusted for different levels of protection, while specialized coating technologies like hydrophobic or ceramic-infused layers are available for enhanced durability. This versatility enables TPU film OEM manufacturers to meet the demands of specific market segments, catering to both mass-market and luxury vehicle applications.

TPU Film vs Vinyl Wrap: What’s the Difference?

While both TPU film and vinyl wraps serve to improve a vehicle’s appearance, they differ significantly in terms of functionality. Vinyl wraps are primarily decorative, used to alter the visual look of a car without offering significant protection. On the other hand, TPU film provides genuine physical protection, safeguarding the vehicle’s paint from scratches, chips, and environmental elements. This is why TPU automotive protective coatings are often used on high-end, luxury, and performance vehicles, where long-term preservation of the car’s appearance is essential.

| Property | Vinyl Wrap | TPU Film |

| Primary Function | Decorative, alters the car’s look | Provides physical protection |

| Protection | Minimal protection | Protects against scratches, chips, and environmental damage |

| Durability | Less durable, may fade or peel | Long-lasting, highly durable |

| Use Case | Primarily for aesthetic changes | Ideal for high-end, luxury, and performance vehicles |

| Maintenance | Requires more frequent maintenance | Low maintenance with self-healing capabilities |

| Cost | Lower cost ($200-$500 per roll) | Higher cost ($500-$1,500 per roll) |

| Top Brands | 3M, Oracal, Elovppf | XPEL, SunTek, Stek, ELOV |

Trends in TPU(Thermoplastic Polyurethane)-Based PPF

As the automotive protection industry evolves, several emerging trends are shaping the future of TPU-based Paint Protection Film (PPF). One notable development is the integration of AI-powered defect detection in TPU films, which allows for better monitoring and maintenance. Additionally, there is growing interest in bio-based TPU alternatives, as manufacturers strive for more eco-friendly options. Another exciting trend is the introduction of smart coatings, which can change color based on temperature, adding an extra layer of personalization and functionality to the TPU film. These innovations will continue to enhance the significance of TPU film in automotive applications, making it a key material in the future of vehicle protection.

Conclusion: Why TPU is the Future of PPF

TPU film is rapidly becoming the go-to choice for Paint Protection Films (PPF) due to its unbeatable combination of flexibility, durability, and clarity. Offering superior protection against scratches, chips, and environmental damage, it maintains the aesthetic appeal of your vehicle for longer periods. Whether you’re a consumer looking to protect your car or an industry professional, TPU film ensures long-term value. Its high-tech, self-healing properties make it a future-proof investment, solidifying its place in the premium PPF market.

Frequently Asked Questions

Which Is Better: TPU or PPF Film?

TPU (Thermoplastic Polyurethane) is actually a type of PPF (Paint Protection Film), and it’s considered the premium option due to its superior flexibility, self-healing properties, and durability. Compared to older materials like PVC or TPH, TPU PPF offers better performance and longevity.

How Long Does TPU PPF Last?

High-quality TPU PPF can last between 5 to 10 years, depending on the environment, maintenance, and driving conditions. Proper care, such as regular cleaning and avoiding harsh chemicals, can help extend its lifespan.

What Are the Disadvantages of PPF Coating?

While PPF offers excellent protection, potential downsides include higher upfront cost, professional installation requirements, and the possibility of edge lifting or yellowing over time if low-quality film is used. However, premium TPU PPF minimizes most of these concerns.

How Much Does a Full PPF Cost?

The cost for a full car PPF wrap varies by brand, car model, and installation quality. On average, a full-body wrap with high-quality TPU PPF ranges from $1,500 to $6,000 or more. Bulk pricing and OEM solutions are available for wholesalers and brand owners.

Can You Take PPF Through Car Wash?

Yes, you can, but touchless car washes are strongly recommended. Automatic car washes with brushes may cause scratches or peel edges over time. Hand washing remains the safest option.

Does TPU PPF Turn Yellow?

Premium TPU PPF made with anti-yellowing technology and UV-resistant coatings resists discoloration for many years. However, low-quality films may yellow over time, especially under intense sun exposure or pollution.