Paint Protection Film (PPF) Industry Standards Guide

Paint Protection Films (PPF) are protective coatings typically applied to automotive surfaces to prevent damage from environmental factors such as stone chips, scratches, UV rays, and chemical exposure. These films are made from high-performance materials like thermoplastic polyurethane (TPU), which provide a transparent, durable, and flexible layer of protection. However, to maintain the high quality and performance of these films across global markets, certain manufacturing industry standards must be followed, ensuring that PPF products meet safety, quality, and performance benchmarks. Below are the main standards and requirements for PPF, which help ensure its long-term stability and effectiveness in various environments.

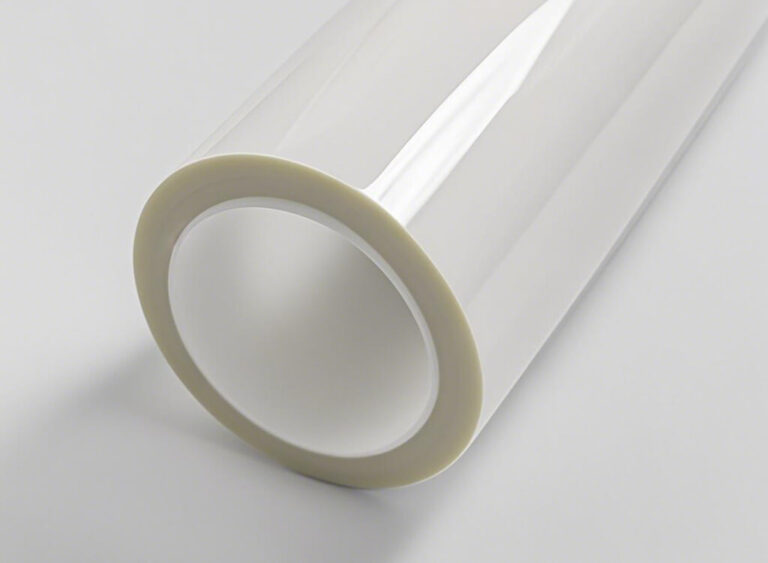

Paint Protection Film Materials and Composition

The ma of PPF plays a crucial role in its protective capabilities. Most PPF films are made from TPU due to its high elasticity, durability, and resistance to abrasions and yellowing over time. For example, ELOV’s automotive paint protection film series is manufactured with Covestro TPU particles as raw materials and undergoes processes such as melting, coating, lamination, cutting, and packaging(PPF Factory Manufacturing). Here are the 3 key substrates often used:

1. TPU (Thermoplastic Polyurethane)

The most common material used in PPF due to its high abrasion resistance, flexibility, and self-healing properties. TPU is ideal for automotive applications because it can withstand physical wear while retaining its transparency and smooth finish.

2. PVC (Polyvinyl Chloride)

PVC-based films are sometimes used for lower-cost applications but do not offer the same level of performance as TPU. PVC films tend to be less flexible, more prone to cracking, and are typically not as resistant to UV degradation as TPU films.

3. TPH (Thermoplastic Polyurethane Hybrid)

TPH is a relatively new type of PPF material that combines the best characteristics of TPU with enhanced performance features. TPH films are designed to provide better chemical resistance, abrasion resistance, and UV stability compared to traditional TPU films. These films offer superior protection against scratches, road salts, oils, and other environmental contaminants. The hybrid structure of TPH films helps balance flexibility and strength, allowing for easier installation and greater durability.

Additives are also used in PPF manufacturing to enhance performance. For example, UV stabilizers and anti-yellowing agents prevent the film from becoming discolored after exposure to sunlight, and hydrophobic coatings make the film water- and dirt-repellent.

Main PPF Physical Performance Standards

According to industry standards, PPF must meet certain physical performance requirements to ensure its long-term protective capabilities.

Physical tests or motheds

| Tests | Method | Standard Requirements |

| Tensile Strength | ASTM D412 | UV Curin≥20 MPa |

| Tear Strength | ASTM D1004 | ≥100 N/mm |

| Elongation at Break | ASTM D882 | ≥200% |

| Abrasion Resistance | ASTM D1044 | ≤15 mg loss (1000 cycles) |

| Weather Resistance | ASTM G154 |

≥2000 hours no yellowing |

| Self-healing | High-temperature self-heal test | Minor scratches self-heal at room temperature |

| Light Transmission | ASTM D1003 | ≥90%g Machine |

Details for PPF Physical Performance Tests

Tensile Strength

Test Method: ASTM D412

Standard Requirement: ≥20 MPa

Description: The tensile strength indicates how much force the film can withstand before it stretches or breaks. High tensile strength ensures durability during installation and after long-term exposure to the environment.

Elongation at Break

Test Method: ASTM D882

Standard Requirement: ≥200%

Description: Elongation refers to the film’s ability to stretch without tearing. This property ensures that PPF can be applied smoothly to vehicle surfaces without breaking.

Tear Resistance

Test Method: ASTM D1004

Standard Requirement: ≥100 N/mm

Description: Tear resistance ensures that PPF can resist damage from sharp objects or impacts without tearing or compromising its protective abilities.

Abrasion Resistance

Test Method: ASTM D1044

Standard Requirement: ≤15 mg of weight loss after 1000 abrasion cycles

Description: This tests how well the film can withstand everyday wear and tear, like dirt and debris, without losing its protective qualities.

Weather and UV Resistance

Test Method: ASTM G154 (UV Exposure Test)

Standard Requirement: ≥2000 hours of exposure with no yellowing or degradation

Description: PPF must remain transparent and protective under prolonged exposure to UV rays, ensuring long-term aesthetic and functional performance.

Self-Healing Properties

Test Method: Thermal Healing Test (e.g., exposure to heat from a heat gun or sunlight)

Standard Requirement: The film should heal from minor scratches within a few minutes to hours when exposed to heat.

Description: PPF films often feature self-healing properties that allow them to restore their smooth surface after being scratched or damaged.

Light Transmission

Test Method: ASTM D1003

Standard Requirement: ≥90% light transmission

Description: Clear PPF must allow high light transmission to avoid obstructing the vehicle’s appearance or lighting.

Paint Protection Film Dimensional Standards

PPF films for cars must meet certain dimensional standards to ensure proper fitment on vehicles and ease of application. The following are typical requirements:

Thickness

Standard Range: 6 to 12 mils (0.006 to 0.012 inches)

Description: The thickness of the PPF is critical for balancing durability and flexibility. Too thick can make installation difficult, while too thin might not provide sufficient protection.

Width

Standard Range: Typically ranges from 18 inches to 60 inches (45.72 cm to 152.4 cm)

Description: The width of PPF rolls determines how much coverage is available per roll, impacting the ease of installation and minimizing seams. Wider films can be used for large surfaces, while narrower ones are often used for custom or complex applications.

Length

Standard Range: Rolls generally come in lengths of 25 feet (7.6 meters) to 100 feet (30.48 meters).

Description: Longer rolls provide more coverage for larger vehicles or larger batches, while shorter rolls are more convenient for smaller applications or custom installations.

Paint Protection Film Chemical Resistance

PPF must be resistant to various chemicals commonly found on the road or in the environment. This includes:

• Gasoline and Oil: The film should not degrade or discolor when exposed to these automotive fluids.

• Salt Mist: Essential for vehicles exposed to road salts in cold climates, ensuring the film remains intact and functional.

• Acid Rain: Resistance to environmental acid rain is vital for maintaining the film’s clarity and protective qualities.

Environmental Adaptability

Automotive Paint Protection Film must perform under a variety of environmental conditions:

• Temperature Range: -40°C to +90°C to withstand extreme heat and cold without cracking or losing its protective properties.

• Water Resistance: The film should not peel or lose adhesion when exposed to water or humidity.

PPF Installation Standards On Car

Proper PPF installation is important for achieving the best visual effects, maximum protection, and extended lifespan of your car’s finish. These are some key installation standards or suggestions:

• Surface Preparation: The vehicle surface should be clean, dry, and free of any oils, dust, or contaminants before applying PPF to ensure maximum adhesion.

• Installation Temperature: PPF should be installed in a temperature-controlled environment. The recommended temperature range for application is typically between 60°F to 80°F (15°C to 27°C).

• Stretching and Conformability: The film should be able to conform to vehicle curves and bends without bubbling, stretching excessively, or distorting.

Certifications and Compliance

PPF manufacturers, factories or suppliers must meet international certifications to ensure quality and consistency, for example:

• ISO 9001: Certification for quality management, ensuring that products are manufactured to consistent and high standards.

• REACH and ROHS Compliance: Ensures that the production process uses safe, environmentally friendly materials.

• ASTM Standards: Widely recognized as the benchmark for testing and certifying the physical properties of PPF.

Additionally, many countries and regions have their specific product testing requirements for imports. For example:

European Union (EU)

E-Mark Certification: Required for automotive products, ensuring compliance with EU vehicle safety regulations.

Japan

JIS Certification: The Japanese Industrial Standards certification applies to a wide range of products.

India

BIS Certification: Issued by the Bureau of Indian Standards, covering various products like electronics, steel, and chemicals.

Saudi Arabia

SASO Certification: Ensures that most imported goods meet Saudi Arabian standards for safety, measurement, and quality control.

At the End

The Paint Protection Film (PPF) industry has developed comprehensive standards that ensure high performance, durability, and ease of application. By using advanced materials like TPU, PVC, and TPH, manufacturers can deliver PPF products that offer superior protection against physical damage and environmental exposure. These standards provide a framework for maintaining the quality and longevity of PPF products, ensuring that they meet the needs of customers across various industries.

Get Premium PPF for Your Business with ELOV!

As a leading Paint Protection Film manufacturer in China, ELOV offers top-quality, durable PPF solutions tailored to your needs. Whether you’re a wholesaler or brand owner, we provide exceptional OEM services and custom solutions to help you elevate your product offering. Contact us today to get the best PPF at factory prices and start growing your business with ELOV’s high-performance PPF!

| ELVO Offers Fast Paint Protection Film OEM |

| 25 Days |

| From Ideas To Mass Production |

| Start OEM For Your Brand Now! |