Car Paint Protection Film Installation Process: The Full Guide

When it comes to keeping your car’s paint looking flawless for years, few solutions are as reliable as paint protection film (PPF). This ultra-clear, highly durable film—often referred to as clear bra film—creates an invisible shield that guards your vehicle against rock chips, scratches, road debris, and even UV exposure. While the benefits of PPF are clear, the installation process itself is a skilled and detailed operation. In this guide, we’ll walk you through the full process of installing car paint protection film, whether you’re a professional installer or a business owner seeking to understand what goes into delivering high-quality PPF services to your customers.

Understanding Paint Protection Film and Its Benefits

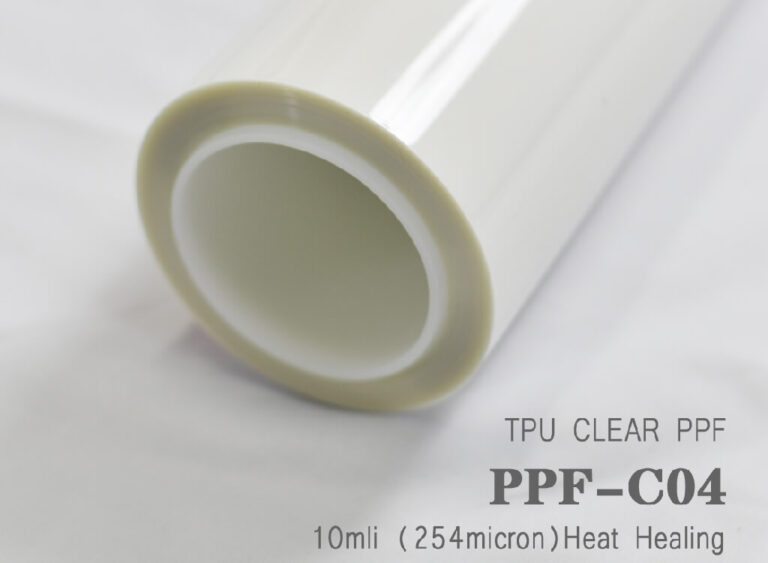

Paint protection film is a thermoplastic urethane material designed to adhere to a car’s painted surfaces and act as a barrier between the paint and external damage. It’s flexible, optically clear, and incredibly resistant to impact, making it a favorite for both luxury and daily-use vehicles. The best paint protection films, such as those made with Covestro TPU, feature self-healing technology, water repellency, anti-yellowing properties, and exceptional clarity. At ELOV, we manufacture PPF with these high-performance characteristics, available in both gloss and matte finishes to match different aesthetic preferences. With growing demand from car owners, dealers, and detailing shops alike, PPF installation has become a valuable business opportunity for wholesalers and brand owners.

Understanding Paint Protection Film and Its Benefits

Paint protection film is a thermoplastic urethane material designed to adhere to a car’s painted surfaces and act as a barrier between the paint and external damage. It’s flexible, optically clear, and incredibly resistant to impact, making it a favorite for both luxury and daily-use vehicles. The best paint protection films, such as those made with Covestro TPU, feature self-healing technology, water repellency, anti-yellowing properties, and exceptional clarity. At ELOV, we manufacture PPF with these high-performance characteristics, available in both gloss and matte finishes to match different aesthetic preferences. With growing demand from car owners, dealers, and detailing shops alike, PPF installation has become a valuable business opportunity for wholesalers and brand owners.

How Much Paint Protection Film Does One Car Need?

The amount of paint protection film required for a single vehicle depends largely on the type of coverage being applied. A full-body PPF installation, which covers every painted surface, including doors, bumpers, fenders, hood, roof, and side mirrors, generally requires between 55 to 75 feet (16 to 23 meters) of film, depending on the size of the car. For standard sedans, installers often use around 60 feet, while larger SUVs or trucks may require closer to 70 or 75 feet.

If the customer opts for a partial PPF package—such as front-end protection only (bumper, hood, headlights, and fenders)—the amount drops significantly. This type of installation typically uses 18 to 30 feet (5 to 9 meters) of film. Other custom areas like door edges, rocker panels, or rear trunk ledges may only require a few additional feet.

| vehicles | PPF | Model Example |

| Microcar, Convertible | 5ft x 50ft | Smart/ Colf cart/Mclaren 720S Spider |

| Coupe, Hatchback, Sedan | 5ft x 59ft | Nissan Sentra/Toyota Prius/Lexus ES/Acura |

| Small SUV, Large Sedan | 6ft x 69ft | Honda CR-V/Toyota Crown/Mercedes-Benz S-ClassBMW 7 Series |

| Large SUV/Vans | 5ft x 79ft | Chevrolet Suburban/Jeep Wagoneer/Ford Expedition |

Car Wrap Installation Tools and Materials

To achieve a flawless car wrap installation, having the right tools and materials is just as important as using high-quality vinyl. From precision cutters and heat guns to soft squeegees and cleaning agents, each item plays a key role in ensuring smooth application, strong adhesion, and a professional finish. Below is a complete list of must-have supplies to help streamline your installation process and deliver showroom-quality results. You need to prepare about 20 tools and materials in total before installation. Below is the tools list(or check on the ELOV Car Wrap Tools page):

-

Paint Protection Film (PPF) – TPU-based, self-healing, clear or matte

-

Plotter or vinyl cutter – for cutting pre-designed film templates

-

Computer with PPF pattern software

-

pH-neutral car wash shampoo

-

Iron remover (for decontamination)

-

Clay bar or clay towel

-

Microfiber towels (lint-free, soft)

-

Isopropyl alcohol (70%-90%)

-

Spray bottles (for slip and tack solutions)

-

Slip solution (distilled water + baby shampoo or install gel)

-

Tack solution (distilled water + alcohol mix)

-

Soft-edge squeegees (various sizes and shapes)

-

Hard-edge squeegee (for firm pressure when needed)

-

Heat gun or steamer (for shaping and activating adhesive)

-

Sharp utility knife or precision cutter (with snap-off blades)

-

Edge trimmer or detail cutter

-

Wrap gloves (lint-free, to avoid fingerprints)

-

Edge sealing pen or PPF edge sealant

-

PPF paddle or corner tucker (for tight curves and edges)

-

Air blower (to dry the surface after wash)

-

Workbench or cutting mat

-

Clean, well-lit, dust-free workspace (essential environment)

Step 1: Preparing the Car Surface: Cleaning and Decontamination

Before any paint protection film can be applied, the surface must be thoroughly cleaned and decontaminated. This is arguably one of the most important steps in the installation process, as any residue, dirt, or particles left behind will be sealed under the film and could lead to bubbles, lifting, or premature failure. Professional installers start by washing the vehicle with a pH-neutral automotive shampoo to remove dust, grime, and oils. After rinsing, an iron remover is used to extract embedded metallic contaminants from the clear coat. A clay bar treatment then follows to eliminate microscopic debris that regular washing can’t touch. Once the surface is fully decontaminated, the vehicle is dried carefully using microfiber towels and air blowers to avoid introducing lint or water spots. This meticulous preparation is what allows the film to adhere properly and perform at its best over time.

Step 2: Inspecting and Correcting Paint Imperfections

Even a brand-new vehicle can have paint imperfections like swirl marks, holograms, or sanding scratches from the factory. These blemishes will be visible throughout the film unless corrected beforehand. That’s why a detailed paint inspection is conducted using specialized lighting to reveal any flaws in the clear coat. If necessary, the paint is polished using a single-stage or multi-stage machine correction process, depending on the severity of the defects. After polishing, the surface is wiped down with isopropyl alcohol to remove polish residues and oils, leaving a perfectly clean and smooth base. This step not only improves the aesthetics of the final result but also helps the paint protection film bond evenly and securely across the entire surface.

Step 3: Cutting the Film: Pre-Cut Patterns vs. Bulk Install

Step 5: Squeegeeing and Securing the Film

After the film is correctly positioned, the installer begins the process of bonding it to the paint by using a soft squeegee. This tool is used to push out all air bubbles and excess slip solution from beneath the film, starting from the center and working outward. The squeegee must be firm enough to remove water but soft enough to avoid scratching the film. Special attention is paid to corners, edges, and body lines, where moisture can get trapped and cause lifting if not fully expelled. Some installers use heat guns or steamers during this stage to help the film conform to sharp curves or recessed areas. When done correctly, this step results in a smooth, crystal-clear finish with no visible bubbles, creases, or haze.

Step 6: Trimming and Wrapping the Edges

Depending on the installation method, some trimming may be necessary around areas like headlights, door handles, or trunk lines. Precision is key here. Any cutting must be done carefully to avoid damaging the paint beneath. In many cases, installers will wrap the edges of the film around the panel for a cleaner, more invisible look and to reduce the risk of dirt getting trapped along the edges. For custom body kits or aftermarket parts, additional shaping and detailed edge work may be needed. The goal is always the same: a seamless application that blends into the car’s original paintwork without drawing attention.

Step 7: Final Inspection and Curing Time

Once the entire vehicle has been wrapped, a final inspection is conducted to identify and correct any small bubbles, lifted corners, or missed areas. At this point, the vehicle enters a curing phase, during which the moisture beneath the film continues to evaporate, and the adhesive bonds fully with the surface. This can take between 24 to 48 hours, depending on the environment. During this time, the vehicle should be kept in a dust-free area and away from water or contaminants. A final wipe-down is performed using a PPF-safe spray, and the installer confirms that every section is smooth, secure, and visually perfect.

Step 8: How to Maintain Paint Protection Film After Installation

Proper aftercare is crucial for maximizing the life of the film and preserving its visual appeal. New installations should not be washed for at least 5 to 7 days to allow for complete curing. After that, owners should use touchless or hand washes with gentle, PPF-safe shampoos. Avoid using abrasive tools, high-pH cleaners, or waxes that can degrade the film’s surface. For those seeking extra shine and protection, applying a ceramic coating designed for PPF can be a great option. This enhances the hydrophobic properties of the film and makes routine cleaning even easier. With proper care, high-quality films like those from ELOV can last up to 10 years or more.

PPF Installation Cost

One of the most common questions from car owners and business clients alike is, “How much does paint protection film installation cost?” The answer depends on several key factors, including the type of vehicle, the areas being covered, the quality of the PPF, and the installer’s experience. For example, a basic front-end package that includes the hood, bumper, side mirrors, and fenders typically ranges from $800 to $1,500 in the U.S. For full car wraps using high-end TPU films like ELOV’s, prices can exceed $2,500 to $5,000 due to the increased labor and materials involved.

Costs are also affected by whether a pre-cut PPF kit or a bulk custom installation is used. Pre-cut kits often reduce labor time and risk, making them more affordable for both installers and customers. On the other hand, full bulk installs offer more seamless coverage and edge wrapping, which demands higher skill and therefore comes at a premium. The brand and performance level of the film also matter—self-healing TPU films with UV resistance and hydrophobic coatings naturally command higher prices due to their durability and long-term protection benefits.

For wholesalers, retailers, and detailing businesses, partnering with a trusted paint protection film manufacturer like ELOV can significantly reduce supply costs. By sourcing directly from the factory at competitive prices and using private-label packaging, you can improve profit margins while delivering top-tier quality to your end customers. Whether you’re targeting budget-conscious clients or the luxury vehicle market, having a flexible pricing strategy backed by a reliable PPF supplier is key to scaling your business effectively.

Conclusion

Both 8 mil and 10 mil Paint Protection Films serve the essential function of preserving your vehicle’s paintwork, each with its own set of advantages. The 8 mil PPF offers a balance of protection and flexibility suitable for general use, while the 10 mil PPF provides heightened defense for more demanding conditions. Assessing your driving habits, environmental exposure, and budget will guide you to the most appropriate choice, ensuring your vehicle remains protected and retains its aesthetic appeal for years to come.

| ELVO Offers Fast Paint Protection Film OEM Services |

| 25 Days |

| From Ideas To Mass Production |

| Start OEM For Your Brand Now! |

| Whatsapp: +85251657739, Email: info@elovppf.com |